Product Category

HMI, Process Controls, Power Supplies

Product

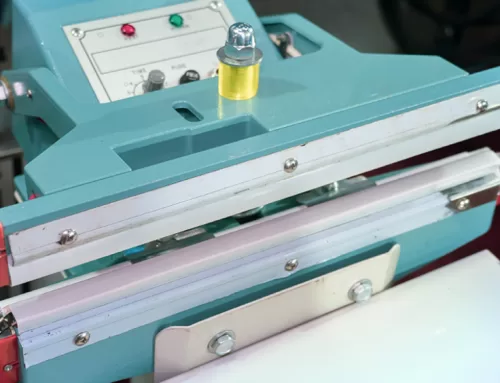

SMPS, PLC, Temperature Controller, HMI

Application

Smoke Density Test Apparatus

Steering Smoke Density Test Apparatus To Peak Performance

Introduction

The Smoke Density Test Apparatus acts like a detective for fire safety by measuring the density of smoke produced by materials when they are burned. This case study talks about the role GIC products play in the smooth functioning of the Smoke Density Test Apparatus and in industries like construction, aviation, and manufacturing.

Challenges

Manual Smoke Density Test Apparatus comes with several big challenges due to its reliance on human operation.

Some of these challenges include:

- Time-Consuming Process

- Data Recording and Analysis

- Calibration and Maintenance

- Inconsistency in Testing

- Subjective Observation

- Safety Concerns

- Proper Skillset

Solution

The PLC-HMI Smoke Density Test Apparatus combines the precision of a Programmable Logic Controller (PLC) with the user-friendly interface of a Human-Machine Interface (HMI). This integrated system enhances efficiency, accuracy, and control in smoke density testing, ensuring a seamless and reliable experience for users.

Result

Precision and Consistency: Minimizes human errors, ensuring consistent test conditions and results.

Efficiency: Automated processes reduce testing time, enabling more tests in a shorter period.

Safety: Minimizes the risk of accidents associated with manual operation through automated control.

Data Management: Automated data logging and storage for easier analysis, comparison, and record-keeping.

The GIC Effect

Cost-Effective Solution.

After-Sales Service Support.

Made in India Product.

Committed for quality product with CE, ROHS certification.

Since ISO Certified organization.