Supply Voltage +

Mode +

Mounting +

Relay +

No. Of Programs +

Display +

Power Reserve +

Clock Accuracy +

Pre-Programmed +

Accessories +

Product visibility +

Analog Input +

Base/Ext +

Bazel type +

Center Distance +

Clock +

Control Action +

Display with & without +

Input/Output +

No. of digits +

No. of set points +

Output +

Output 1 +

Output 2 +

Output 3 +

Product Type +

Read Out +

Register +

RS485 Communication +

Sensor Input +

Size +

Termination +

Contact +

Delay +

Enclosure Design +

Function +

Input Voltage +

Output Current +

Output Voltage +

Power +

Relay Output +

Supply +

Timing Range +

Variant +

Alarm Output +

Analog Output +

Auto Reset time +

Auxiliary Supply +

CBCT Size +

Colour +

Current Range +

Digital Display +

Digital Input +

Digital Output +

Display Colour +

High Speed Inputs +

Input Signal +

LCD Display +

Leakage Current +

Module +

Neutral Loss +

Output Signal +

Over Frequency +

Over Voltage +

Phase Asymmetry +

Phase Loss +

Phase Sequence +

Reset +

Sensor Supply +

Series +

Settable Off Delay +

Settable On Delay +

System +

Transistor Output +

Under Frequency +

Under Voltage +

Voltage +

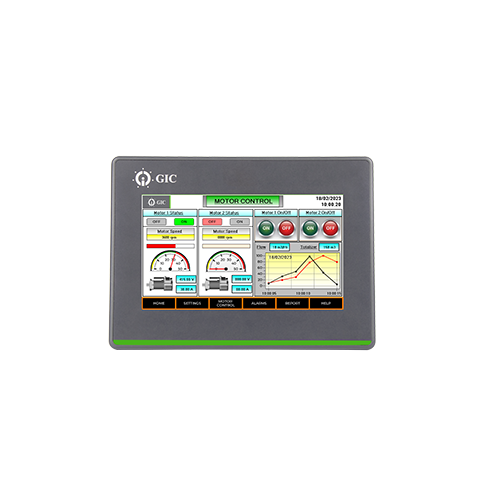

What is Human Machine Interface (HMI)?

Human Machine Interface (HMI) also known as Operator-Machine Interface is a technology that enables effective interaction between humans and machines. It serves as a user-friendly interface, allowing operators to monitor and control industrial processes. By integrating touchscreens, graphical displays, and input devices, HMI systems provide intuitive and interactive interfaces.

HMI plays a crucial role in industries like manufacturing, automation, energy, and transportation, enhancing operational efficiency and safety. Operators can access real-time data and monitor variables such as temperature, pressure, and equipment status through visually appealing graphical representations. HMI and Human Machine Interface are synonymous terms, representing the technology that facilitates human interaction with machines.

HMI systems are essential for effective operator machine interfaces, providing a user-friendly interface that simplifies complex processes. They enable operators to monitor real-time data, control equipment, and make informed decisions. HMI enhances productivity by offering intuitive graphical representations of variables such as temperature, pressure, and equipment status.

Importance of HMI?

HMI systems find applications in diverse industries. In manufacturing, operators can use HMI to monitor production lines, adjust settings, and detect anomalies promptly. In energy management, HMI facilitates monitoring power generation, optimizing energy consumption, and ensuring safe operations. Transportation systems utilize HMI panels for monitoring vehicle status, controlling navigation, and ensuring passenger safety.

An example is a control room in a chemical plant. Operators use HMI systems to monitor various parameters, control valves and pumps, and respond to critical situations promptly. HMI provides real-time data visualization, alarms, and alerts, enabling operators to maintain process stability and prevent incidents.

What are Touch Screen HMI?

Touch Screen HMI refers to systems that incorporate touch-sensitive screens, allowing operators to interact directly with the interface using their fingertips. These intuitive interfaces have revolutionized the way operators interact with machines and control industrial processes.

Benefits of Using Touch Panel HMI?

HMI touch panels offer numerous benefits for industrial applications. With enhanced visibility, operators can view critical information on a high-resolution HMI touch display. Increased efficiency is achieved through intuitive interfaces, reducing task completion time. HMI panel also contribute to decreased downtime with real-time alerts and diagnostics. Improved usability simplifies operations and reduces errors.

Enhanced Visibility

HMI touch panels offer enhanced visibility with their high-resolution HMI touch display, providing clear and vibrant visuals. This enables operators to view critical information and data in real-time, improving situational awareness. For example, a HMI with a touchscreen interface allows operators to monitor and control production parameters with precision.

Increased Efficiency

HMI panel streamline operations by offering intuitive and user-friendly interfaces. Operators can navigate menus, access data, and make adjustments swiftly, reducing the time required for task completion. This enhances operational efficiency and productivity. For instance, a HMI with touch functionality enables operators to quickly adjust machine settings and optimize production processes.

Decreased Downtime

They contribute to minimizing downtime through their advanced diagnostic capabilities. They provide real-time feedback, alerts, and notifications about system performance and potential issues. Operators can promptly respond to alarms and perform troubleshooting, preventing extended downtime.

Improved Usability

Touch Panel HMIs offer improved usability with their intuitive touch interfaces. Operators can interact directly with the screen, eliminating the need for complex manual controls or extensive training. This simplifies operation and reduces the chance of errors. For instance, an Ethernet HMI with touch functionality provides seamless control of a building automation system, allowing users to manage lighting, temperature, and access control effortlessly.

In conclusion, Human-Machine Interface is a critical aspect of modern technology that enables us to interact with machines and devices in a more intuitive and user-friendly way. It plays a vital role in the development of automated systems and can improve safety, efficiency, and productivity in a wide range of industries. As technology continues to evolve, we can expect HMI to play an even more significant role in shaping the way we interact with machines and devices.

Frequently Asked Questions

The key features and functionalities of GIC HMI’s products are:

- “4.3”, 7” & 10.1” with colour TFT display options with & without Ethernet model

- Equipped with powerful CPU Cortex-M7 (600MHz)

- Higher brightness level of upto 440 cd/m2 & long backlight life of up to 50000 hours for display

- Application upload/download function available via USB Slave, USB Host, SD Card, Serial & Ethernet Port

- Data logging function available via Internal Memory, USB Host, SD Card

- Real-time trend & historical trend support

- User access levels & application password management

- Inbuilt picture library with high-resolution images

- IP 65 protection for the front panel with Class 2 Pollution Degree

- PCB conformal coating protection

- CE, RoHS Compliant

Consider the following parameters while selecting:

- Display size

- Ethernet/Nonethernet model

- USB Stick/SD card interface

- Communication interface

- Memory (RAM/ROM)

- Required features(Special Features)

Yes, GIC HMI supports the PLC series of AB, Siemens, Delta, IDEC & GIC.

One of the key differences between a PLC and an HMI is their primary function. While a PLC is responsible for executing control logic and managing inputs and outputs, an HMI focuses on providing a user-friendly interface for operators to interact with the system.

4.3”, 7” & 10.1” with colour TFT display

In medical environments, HMI systems allow healthcare professionals to monitor and control various medical devices, improving patient care and safety.

HMI helps businesses to enable their employees to perform tasks with the help of automation tools to increase efficiency, reduce the cost of labour and reduce the risk of human errors.

Some examples of common Human Machine Interface devices that we encounter in our daily lives include touchscreens and keyboards. HMIs utilized in the industrial context are mostly screens or touchscreens that connect users to machines, systems or devices.

The Human-Machine Interface (HMI) provides an important visual of what is going on inside the control system. It is also an easy way to see multiple events in real time. It is mainly providing better safety to operator, increase productivity and create troubleshooting easier.