Product Category

Process control

Product

PL100 PLC, GSM Alarm Modem, HMI, SMPS

Application

Fire Alarm System.

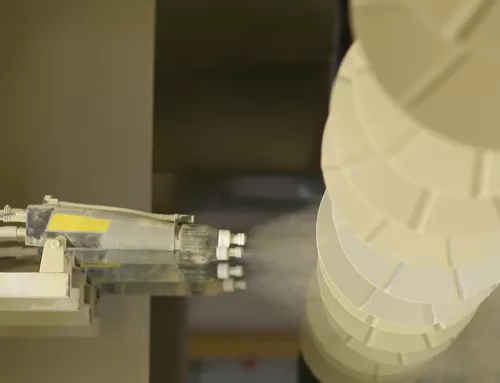

Slicing Through Challenges.

With Genie-NX Enhanced Conduit Cutting.

Introduction

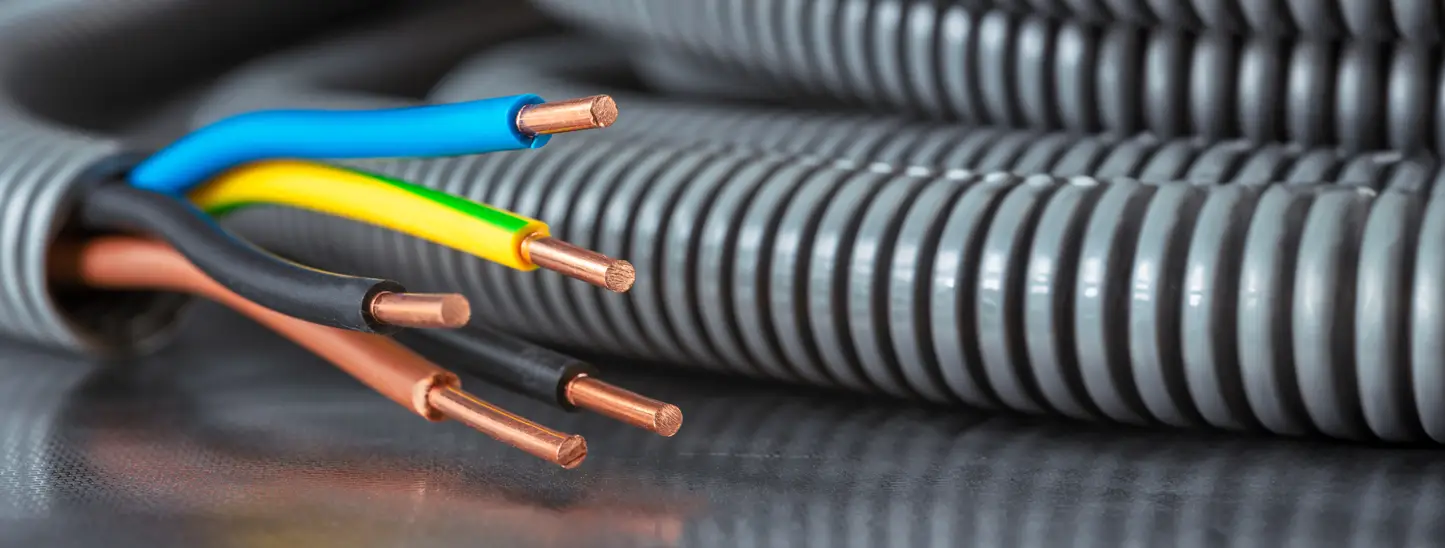

Pneumatic Operated Electrical Conduit Cutting Machines have revolutionized the Electrical conduit manufacturing industry. Among the key players in this transformation stands GIC, with its cutting-edge Genie NX – G7DDT11 PLC. These machines operate efficiently through the force of compressed air, proving to be indispensable for conduit manufacturing companies.

Challenges

In the pre-GIC era, our client grappled with quality issues and soaring rejection rates. They relied on counters of some other brands and a local-made timer for their automatic cutting machines. However, these components proved limiting, causing improper cuttings and a myriad of quality problems. The existing setup was semi-automatic, with various products interdependent on one another, further complicating the scenario.

Solution

The arrival of Genie-NX PLC heralded a transformation in this landscape. GIC’s experts developed a logical solution that addressed the quality and operational issues. They ingeniously integrated Genie-NX PLC, not only resolving the timer limitations but also facilitating Batch count and Total count displays. The success of this implementation was so profound that the client is now phasing out complex wiring machine panels, replacing them with the simplicity of a single Genie-NX device.

The GIC Effect:

The deployment of GIC’s Genie-NX PLC in Conduit Cutting Machines has ushered in a multitude of benefits:

Structured Cutting Operations: The machines now perform cutting operations in a highly structured and precise manner, ensuring consistent quality.

Enhanced Product Quality: Quality-related woes have become a thing of the past. The implementation has significantly improved product quality, reducing rejection rates.

Enhanced Operator Safety: GIC’s solution has made operations safer for the workforce, eliminating potential hazards.

Boosted Work Speed: With increased efficiency, the machines operate at a higher speed, effectively shortening overall production times.

Simplified Wiring: Complex wiring panels are being phased out, simplifying the machine’s setup and reducing maintenance hassles.

Why Choose GIC

Cost-Effective Solutions: GIC offers cost-effective solutions without compromising on quality or performance.

After-Sales Support: A dedicated after-sales support team ensures that clients get the most out of their GIC products.

Made in India Product: GIC’s commitment to “Make in India” is not just a slogan but a testament to their dedication to the nation’s growth.

Quality Assurance: GIC’s products come with CE and ROHS certifications, underscoring their commitment to delivering high-quality solutions.

ISO Certification: As an ISO-certified organization, GIC maintains stringent quality control measures at every stage of product development.

In the realm of Electrical Conduit Cutting Machines, GIC has not only delivered cutting-edge technology but has also transformed the way the industry operates, setting new standards for efficiency, quality, and safety.