Product Category

Process Controls

Product

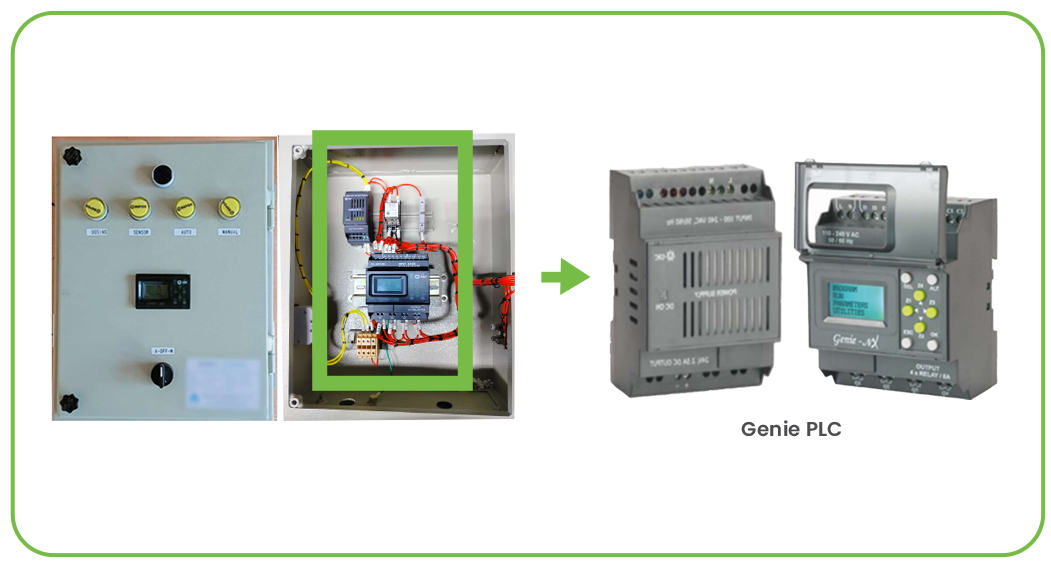

Genie PLC

Application

Water Treatment Processes

GIC Genie PLC: Making Waves in Water Treatment

Introduction

In the realm of water treatment, the precision of chemical dosing is paramount. This case study explores the integration of Genie PLC (G8DDT11) into an automated dosing system, showcasing its pivotal role in maintaining optimal water quality.

Challenges

Traditional dosing systems were marred by manual interventions, leading to errors and inefficiencies in water treatment processes. The reliance on traditional methods hindered the effectiveness of water treatment due to these inherent challenges.

Result

The incorporation of automated dosing systems not only eradicates manual errors but also enhances accuracy by utilizing sensor inputs. All while ensuring substantial cost savings through the seamless automation of time intervals with Programmable Logic Controllers (PLCs)

Solution

Enter Genie PLC—the game-changer. The system now operates seamlessly, employing chlorine dosing based on time intervals and demand control, closely monitored by a water level controller. This PLC introduces the flexibility of both auto and manual control options.

GIC’s Genie PLC offers several benefits when used in automated dosing controllers for water treatment and other industrial processes:

The GIC Effect

Cost-Effective:

GIC’s solution provides cost-effective automation, ensuring maximum value for investment.

After-Sales Support:

A commitment to customer satisfaction with robust after-sales service.

Made in India:

GIC’s products are proudly manufactured in India.

Quality Assurance:

Products hold CE and ROHS certification, reflecting GIC’s commitment to quality.

ISO Certification:

Operating as an ISO-certified organization, GIC ensures adherence to global standards.