Product Category

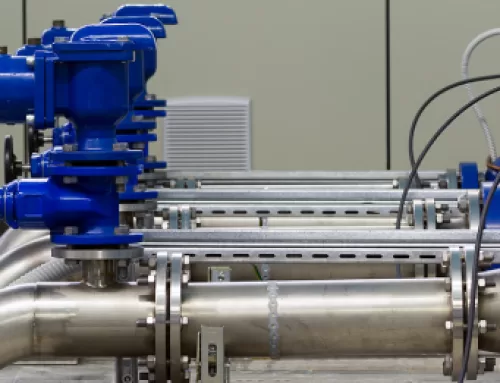

Process Control

Product

Programmable Logic Controllers (PLC) – Smart Relay & Mini PLC

Application

Pressure Booster Pump Control (Industrial & Residential)

Task

Trend towards taller buildings and condensed living are resulting in water flows varying significantly throughout the day in buildings, placing extraordinary demands on pumping equipment. PLC controlled Variable speed pressure boosting systems are designed to handle these challenges and provide adequate and constant water pressure. This is to operate pumps in alternate sequence based on pressure input to maintain required water pressure in Industrial & residential buildings.

The Solution

PLC controlled booster pump controller helps to manage up to four pumps for constant pressure with the variable speed drives that gives significant advantages than the conventional manual system.

Auto Mode:

In the beginning, the system uses pump no. 1 only. If the pressure changes from the set value, the PLC gives command to drive to adjust the speed of pump no 1 to keep the pressure at the set value. If the pressure decreases and drive velocity is 60 Hz, the PLC gives command to use pump no 1 and pump no 2 to keep the pressure at the set value. The system continues using pumps no 3 and no 4 in like manner to keep the pressure at the set value. If the pressure increases and the pump no 4 drive velocity is 0 Hz, then PLC gives command to stop pump no 4 and use pumps no 3, no 2 and no 1 to keep the pressure at the set value. If the pressure continues to increase and the pump no 3 drive velocity is 0 Hz, then the PLC gives command to stop pump no3 and uses pumps no 2 and no 1 and so on. Finally, if the pressure is at the set value and pump no 4 drive velocity is 0 Hz, the system goes to sleep to save energy.

Benefits

Constant Pressure Control

The PLC controls Drives to vary speed of the pump for constant pressure at the outlet.Optimized Costs

PLC control offers a highly competitive performance/cost ratio.Energy Savings

The pump consumes power only when required (as low as possible). PLC controlled system stop the pumps when there is low or none of water demand.- Easy to Use

The users can adjust the pressure (set point) and identify fault alarm directly on easy-to-use interface with PLC.